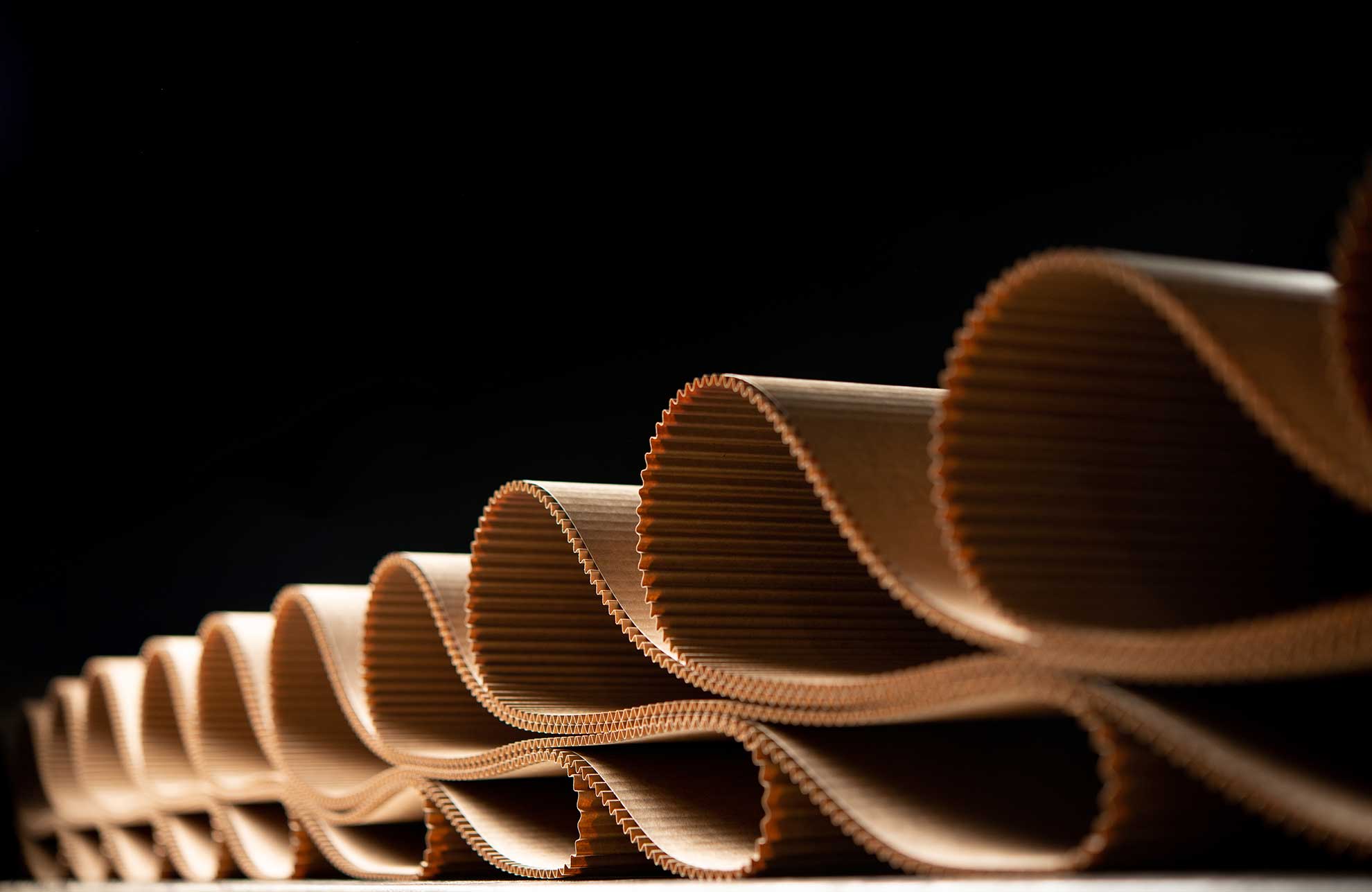

Molded Fiber

The molded fiber market is expanding rapidly, driven by regulatory pressure on plastics and the demand for recyclable, PFAS-free food packaging. Mills must adapt their processes to improve product appearance, barrier performance and runnability, to scale up capacity, while maintaining environmental compliance and energy efficiency.

Specificities of this Paper

Molded fiber requires optimized drainage and fiber bonding for uniform surface quality and mechanical strength. Producers must achieve fast dewatering, smooth formation, and effective barrier coating compatibility, while using renewable and recyclable raw materials.

Discover our solutions for:

Axchem's Role in Improving Efficiency

Axchem supports molded fiber producers with integrated chemical solutions that act throughout the production process to enhance efficiency, quality, and sustainability. At the wet end, AXSTRENGTH® BM series improves fiber and filler retention, ensuring faster drainage and a more homogeneous sheet formation. This creates the foundation for better runnability and reduced fiber losses. Building on this improved formation, AXFOAM® controls foam and entrained air, stabilizing the process and maintaining even fiber distribution — a key factor for achieving smooth surfaces in thermoformed molded fiber applications. Once the structure is stable, AXSTRENGTH® BM enhances dry and wet strength, enabling lightweight yet resistant products that meet handling and stacking requirements while preserving recyclability. To complement mechanical performance, AXSIZE® improves sizing efficiency, strengthening resistance to water and grease and ensuring perfect adhesion for coating stages.

From Fiber to Form — Sustainably.

Molded fiber represents a strategic segment in the shift toward sustainable packaging. Axchem’s chemistry enables mills to meet performance, regulatory and environmental goals, offering reliable alternatives to plastic packaging and contributing to circular economy objectives.

Our products related to this type of paper