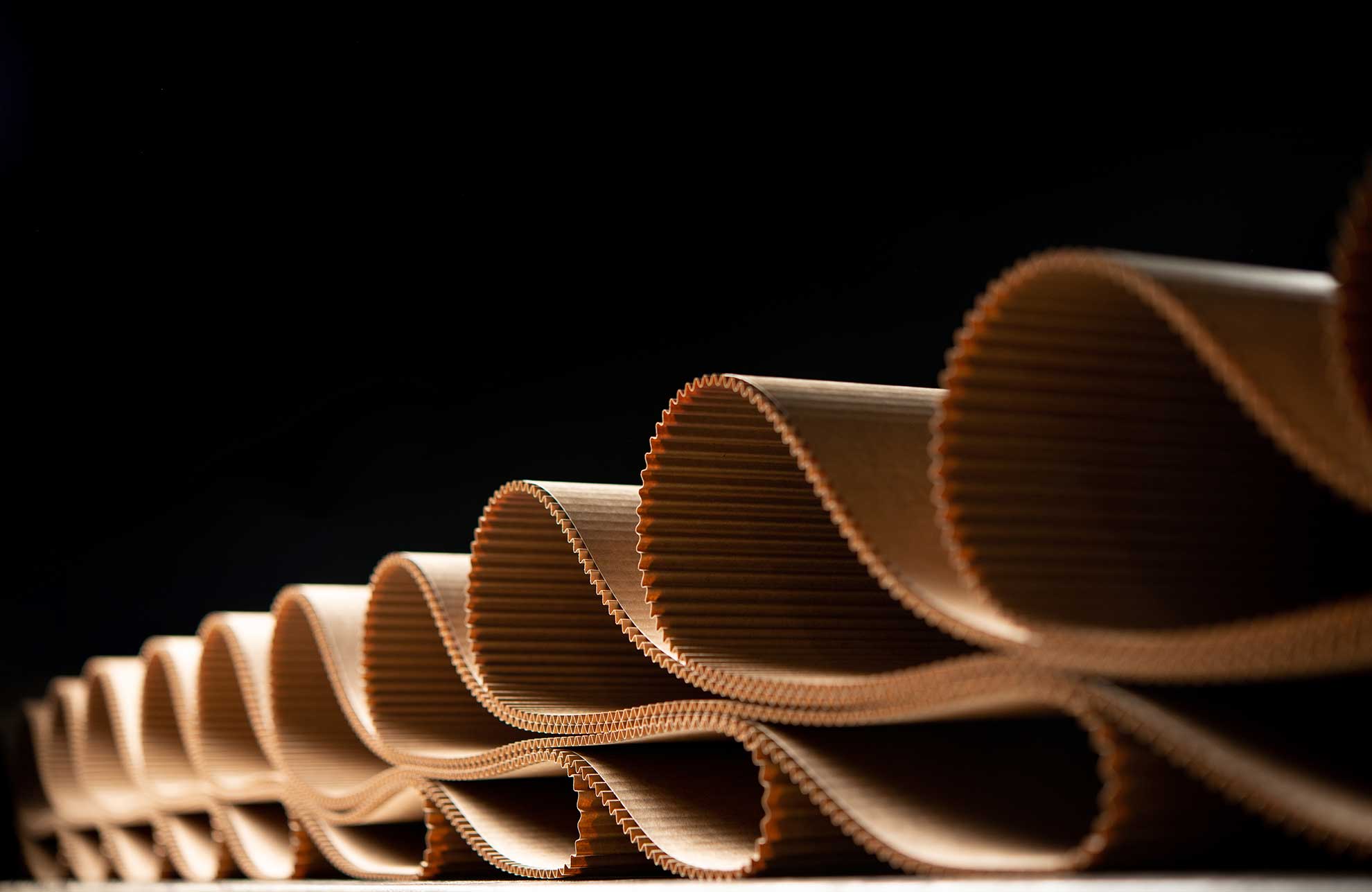

Neutralizes Stickies, Stabilizes Wet-End Chemistry, and Secures Sheet Quality.

AXFIX® is a comprehensive contaminant control program designed to neutralize and fix problematic substances in the papermaking process. From stickies and pitch to colloidal trash and resins, AXFIX® prevents agglomeration, deposition, and machine instability. By protecting wires, felts, and wet-end chemistry, it enables smoother operations, fewer shutdowns, and more consistent sheet quality — particularly in recycled fiber environments where contamination loads are high.

Reliable Fixation That Improves Runnability

AXFIX® combines organic and inorganic coagulants to capture hydrophobic materials, dyes, sizing agents, and unwanted colloids. Acting in synergy with retention systems, it secures valuable chemicals in the sheet while eliminating disruptive anionic contaminants.

This Leads to:

- Fewer cleaning interruptions

- More stable wet-end performance

- Enhanced productivity and paper quality

Sustainable Contaminant Control for Greener Production

Key Benefits of AXFIX®

- Tailored programs for each mill’s contaminant profile

- Seamless integration with existing wet-end operations

- Proven reduction in downtime from stickies and pitch deposition

- Extended wire and felt lifetime through cleaner loops

- Stable sheet quality even under high-recycled fiber conditions

- Supported by local technical expertise for fast issue resolution

It Supports Mills Aiming to:

- Increase recycled fiber usage

- Drive higher machine speeds

- Improve wet-end stability for consistent production

Ressources

Brochure & Technical information

Check out our detailed data sheet for precise information.

Part of the AXCHEM Range